| The research experience of the QUAD laboratory is primarily in the field of monitoring and analysis of business and manufacturing processes for quality and reliability improvement. Significant synergies were found when multidisciplinary engineering technologies, advanced statistics, and data mining techniques were integrated. My research accomplishments include: |

|

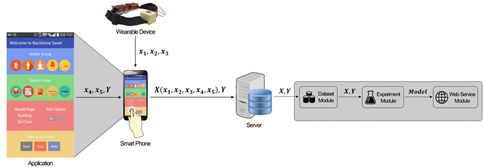

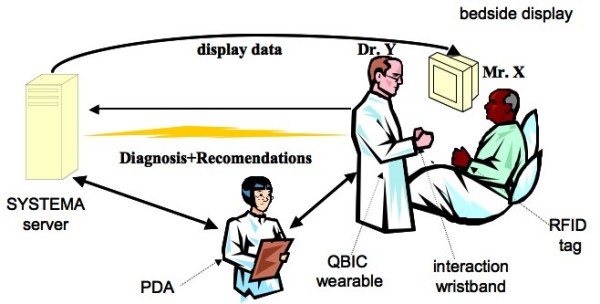

Developing a predictive model for personalized context-aware warning system for low back pain |

|

|

Big Data Analysis Based Recommendation System for Pregnant Women (Associated with Cha Hospital in South Korea) |

|

|

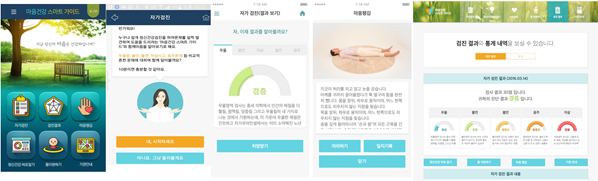

Web-Based Mental Health Self-Screening, Managing and Connective System |

|

|

Privacy Protection System Prototype (University Creative Resource Commercialization Project) |

|

|

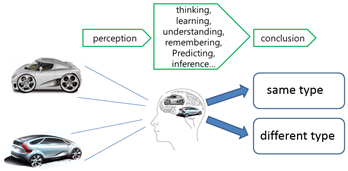

Cognitive Model-Based Design for Product Differentiation and Optimized Advertising Strategy |

|

|

Research Project on the Development of Data Mart based on the Big Data Analysis of Slope Collapse |

|

|

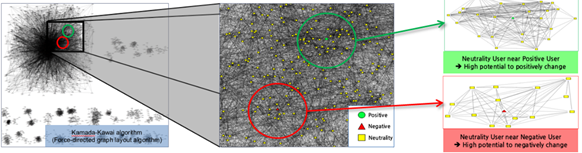

Research on the Development of Social Safety net using Big Data Analysis |

|

|

Tourism Market IT analysis using the big data of roaming services |

|

|

The 2nd Data Mining Contest Administrating Project- Roaming Data of Inbound Foreign Tourists |

|

|

Quality Assessment of Occupational Radiation Exposure Analysis and Database for Radiation Workers in Korea |

|

|

Non-parametric statistical method and confrontation strategy for effective analysis of occupational radiation exposure in a nuclear power plant |

|

|

Research on Estimation of Reasonable Price and Repetition of Research Equipment |

|

Likelihood-based Bayesian Method for Assessing Process Risk in Real Time Process consists of a set of activities to accomplish predetermined goal. An instance of process ends up with achieving its goal or not. Early detection of undesired situations will increase the process performance and reduce the loss of resources. Monitoring in real time all the activities involved in service and manufacturing processes is of value. We have developed a likelihood-based Byesian method to estimate the undesired achievement probability of process instances in real time. The estimated probability could be used as a precaution for the worst or a basis for go/no-go decision. |

|

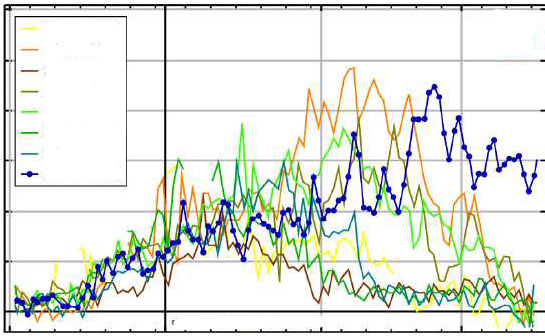

Developing and designing monitering methods of multiple changes The ultimate objective of the research is to develop and optimally design methods monitoring multiple types of changes simultaneously. This research contributes to satisfy the magnifying demand for monitoring various types of changes in manufacturing industry, service industry, network security, medical science, environment science, biology, genetics, pharmacy, finance, law enforcement, sports and so forth. This research also contributes to providing an optimal design approach to conventional combined control charts, providing a novel perspective to combined control chart approaches, allowing to simultaneously monitor more than three types of changes, magnifying the application of SPC based monitoring methods and the resulting financial benefits, and promoting domestic SPC softwares to be more competitive. |

|

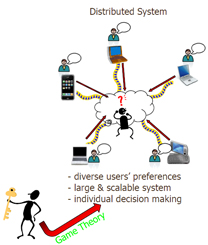

Game Theoretic Approach for Cross-layer Design in Wireless Communications Most game-theoretic works of Aloha have emphasized investigating Nash equilibria according to the system state represented by the number of network users and their decisions. In contrast, this research focuses on the possible change of nodes' utility state represented by delay constraint and decreasing utility over time. These foregone changes of nodes' state are more likely to instigate selfish behaviors in networking environments. For such environment, in this research propose a repeated Bayesian slotted Aloha game model to analyze the selfish behavior of impatient users and proved the existence of Nash equilibrium mathematically and empirically. The proposed model enables any type of transmission probability sequence to achieve Nash equilibrium without degrading its optimal throughput. Those Nash equilibria can be used as a solution concept to thwart the selfish behaviors of nodes and ensure the system stability. |

|

Developing Statistical Process Control Based Health Surveillance Methods The objective of the research is to develop SPC-based monitoring methods in public-health and person-health which are closely related to the everyday life. The research is motivated by the common purpose between SPC and health surveillance, which is to detect abnormal change timely. The SPC-based Public-health surveillance system can be used to proactively avoid the spread of diseases. It would result in much reduction of financial loss nation-wise and individual-wise. |

|

Optimal Design of Control Charts for Autocorrelated Processes Automated in-process measurement commonly generates intricate temporal patterns in densely-spaced autocorrelated process data. Traditional SPC techniques, such as control charts, assume independent data and do not perform well with autocorrelated data. |

| Two new control charting schemes were developed by considering the control chart as a linear filter. Automatic, systematic strategies for optimizing the new control charts were also developed. The optimized new control charts outperform existing control charts in many situations. The most substantial performance gain was seen with autocorrelated data like that found in the data-rich environments my future research will address. |

|

|

Development of a Customized SPC System Two primary characteristics of aircraft assembly processes that make implementation of traditional SPC methodology difficult are: (1) limited production and inspection rates, and (2) a large variety of different features measured on each part. Key Product Characteristics (KPC) and Key Control Characteristics (KCC) were identified and used to develop a process-oriented SPC system tailored to the highly specialized manufacturing processes. |

| One of the main philosophies behind the developed system is that, with a large number of critical features to monitor, the ability to analyze measurement data at different resolution levels is essential. The system was used as a means of understanding and tracking quality and detecting "early-warning" signs of quality degradation. This early-warning feature was designed to reduce manufacturing costs through defect prevention, resulting in reduced scrap and rework. A general framework will require the ability to perform analysis at varying resolution levels. |

|

| |

Utilization and Integration of All Printed Circuit Board (PCB) Inspection Data Extensive inspection data from various sensors at various stages of the PCB manufacturing process is typically used only to classify a feature as within or outside specification limits. Ignoring their interrelationship results in a significant loss of useful monitoring, diagnostic, and decision-making information. |

| This research improved utilization and integration of inspection data, thereby allowing manufacturers to achieve higher yield and reliability, lower manufacturing costs, and an improved process understanding. |

|

|

Development of an Automated Inspection System In some critical applications such as the aerospace or medical industries, all of the parts must be inspected. Many manufacturers also desire complete inspection for a higher quality of product. Coordinate Measuring Machines (CMM) are widely used to examine the conformity of manufactured parts with their specifications in 3D sizes, positions, and forms. CMMs generate extremely spatially dense (point cloud) data. A tremendous quantity of geometric data and its spatial density is beyond the capacity of traditional inspection techniques and visualization methods. For rapid inspection and easy interpretation, an automated inspection system was presented using a 3D visualization software. The system first imports a point cloud data collected by a CMM and registers it with a CAD model of the part. Then, the geometric tolerances are checked using the 3D data and the CAD model. A color-coded map annotated for easy comparison and analysis is generated to illustrate deviations between the measured points and the CAD model. |