GRANTS AND CONTRACTS

Department of Industrial and Management Systems Engineering, Kyung Hee University, Republic of Korea

|

|

"Developing a Big Data Analysis Based Recommendation System for Pregnant Weman, Associated With Bundand Cha Medical Center", Korea Technology and Information Promotion Agency for SMEs, August 2015 - July 2016

|

|

"Developing Web-based Screening, Coaching, and Referral system for Mental Health Promotion", Ministry of Health & Welfare, September 2015 - December 2015

|

|

"Designing products to be maximally differentiated with others and establishing optimal advertising strategies based on cognitive models", National Research Foundation of Korea, November 2014 - April 2016

|

|

"Pilot Project on Disaster Management Using Big Data", LX Korea Cadastral Survey Corp., November 2014 - December 2014

|

|

"Managing Data Mining Competition", Korean Culture & Tourism Institute, March 2014 - June 2014

|

|

"A Study on Building Social Safety Net Using SNS Big Data", Korea Foundation for the Advancement of Science & Creativity, September 2013 - February 2014

|

|

"Research on the Countermeasures to Reduce the Occupational Radiation Exposure for Long-term Operated Nuclear Power Plants", Korean Hydro & Nuclear Power Co., Ltd., May 2013 - December 2013

|

|

"Advanced Study on Determining the Duplication and Reasonable Price of Research Equipment", National Research Facilities & Equipment Center, October 2013 - December 2013

|

|

"Trend Analysis and Quantitative Optimization Evaluation of Nuclear Power Plant Radiation Worker Doses with Using Advanced Statistical Methods", Korean Hydro & Nuclear Power Co., Ltd., September 2012 - August 2013

|

|

"Developing and Designing Monitoring Methods of Multiple Changes", National Research Foundation of Korea (NRF), September 2010 - August 2012

|

|

"Developing Statistical Process Control Based Health Surveillance Methods", Korea Research Foundation (KRF), May 2009 - May 2010

|

|

"A Study on Constructing a Flexible Control Chart for Autocorrelated Data", Korea Research Foundation (KRF), July 2008 - July 2009

|

|

"Application of Game Theory to Mobile Communications", Institute for Information Technology Advancement (IITA), April 2008 - March 2011

|

|

"Technical Support for the Development of uSPC system", Yongin-si Technical Support Program, October 2007 - September 2008

|

|

"Dimensional Statistical Process Control for Low-Volume Production", Kyung Hee University, September 2005 - August 2006

|

PROJECTS AT TEXAS A&M UNIVERSITY

Department of Industrial Engineering, Texas A&M University, College Station, TX, June 1999 - August 2004.

|

|

TITLE: Characterizing and Diagnosing Manufacturing Variation with In-process Measurement Data

SPONSORS: NSF and Texas Advanced Technology Program.

OBJECTIVE: To develop a methodology that, like statistical process control (SPC), aids in understanding and reducing part-to-part variation, but that is tailored to spatially and temporally dense dimensional data.

|

Development of statistical methods for characterizing the nature of spatial and temporal variation patterns. |

|

Development of interactive computer graphics methods for most effectively visualizing the variation patterns. |

|

Identification and elimination of root causes of manufacturing variability. |

|

|

|

|

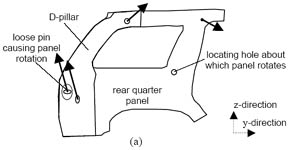

Figure 1. Autobody Assembly Process. Graphical Illustration of Spatial Patterns Identified in Quater Panel Subassembly. |

|

|

|

|

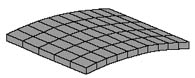

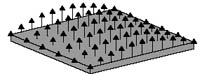

Figure 2. Volume (left) and Glyph (right) rendering of a variation pattern that represents bending.

|

|

|

TITLE: Defect Detection and Prevention in Printed Circuit Board Assembly via Information Integration

SPONSORS: Solectron Texas and Texas Advanced Technology Program.

OBJECTIVE: To develop a framework for full utilization and integration of all available Printed Circuit Board (PCB) inspection data from various sources such as X-ray laminography and laser optical inspection machines.

|

Understanding and characterizing the interrelationship between inspection data from various sensors, defect likelihood, root causes of defects and process degradation, and Printed Circuit Assembly (PCA) reliability. |

|

Development of methodologies for defect and process monitoring with threshold adaptation and root cause diagnostics. |

|

On-line diagnostics and decision making. |

|

Improvement of defect detection and prevention. |

|

|

|

|

Figure. Printed Circuit Board (PCB) and Solectorn Texas Logo

|

|

|

TITLE: Statistical Process Control for Low-Volume Composite Manufacturing

SPONSORS: Bell Helicopter Textron Inc.

OBJECTIVE: To develop the framework and guidelines for implementing a statistical process control (SPC) methodology for Quality Assurance (QA) and demonstrate the potential of SPC for improving quality and reducing scrap/rework.

|

Analysis of airframe assembly process and rotor blade fabrication sequence. |

|

Feature extraction: Identification of Key Product Characteristics (KPCs) and Key Control Characteristics (KCCs) for the processes. |

|

Development of statistical process control (SPC) methodology guidelines. |

|

Development, implementation, and demonstration of pilot statistical process control (SPC) systems. |

|

|

|

|

The V-22, Bell Hellicopter Textron Inc.

|

|